EVs Alone Aren’t the Answer

EVs Alone Aren’t the Answer

Richard Briggs, Transport Manager at EECA, shares the government’s stance on what else transport businesses should be doing to reduce their overall carbon emissions.

Everyone’s talking about electric vehicles these days, especially fleet operators. Given that transport accounts for 41% of energy sector emissions, decarbonising fleets seems like the obvious approach to solving the global carbon crisis.

But for the Energy Efficiency & Conservation Authority (EECA), decarbonisation is a complex process requiring long-term commitment, and switching to EVs is just one piece of the big picture. Because technology, market availability, and infrastructure are limiting factors and will continue to be for some time, fleet operators must take a comprehensive approach to controlling their carbon output now.

EECA Transport Manager Richard Briggs is the first to admit that no one has all the answers and we’re all learning as we go. In the past, EECA was focused on EVs as the primary solution, but the market is evolving:

“Transitioning 4.5 million cars to 4.5 million EVs doesn’t fix the problems. If you want a sustainable fleet, you’ve got to get vehicles off the road.”

The remaining vehicles, the ones you must have to operate, should then be EVs.

Why Focus on Light Vehicles?

The issue is that heavy EVs simply aren’t available in any great volume, as OEM trucks are still in their infancy. Most are in the early production phase and supply is extremely limited, confined mainly to the sub-10-tonne urban delivery truck. Even if an organisation is keen to transition their heavy fleet, they can’t yet do so at scale. However there are gains to be had by focusing effort on achieving operational efficiencies and route optimisation to reduce carbon output.

Passenger EVs, however, have been around for a while now; the first Nissan Leaf came out in 2011. The market has had at least 10 years to mature so there’s now a reasonable volume of vehicles to choose from, both new and used, and as the technology continues to mature, prices will drop sharply. Analysts predict price parity with internal combustion vehicles by 2025/26, so buying an EV in four or five years willbe a no-brainer.

Given that most fleet cars don’t have telematics because they’re a cheaper asset relative to a heavy vehicle, and typically not driven as far, light vehicle utilisation has been overlooked until recently – but it shouldn’t be, as that’s where you can make cuts right now

Start by Taking Stock

Aim to reduce fleet size, particularly where you may be over-resourced for your actual needs.To gain an accurate understanding of your current needs, take a hard look at what you’re doing and why. Start by asking, “Do I need to move people and goods in my business? If so, what is the most sustainable way of doing that? If not, why do we have these vehicles?”

COVID has transformed the way people do business and eliminated a lot of unnecessary travel that was once de rigueur.

“Many organisations could reduce their fleet by around 20% without any impact at all on business productivity,” says Briggs. “It’s just about being smarter in how you move your people and goods.”

For some businesses, cost is another limiting factor, but Briggs points out that if you can achieve a fleet reduction of 20% or 25%, moving to EVs suddenly becomes more affordable:

“While the cars are more expensive, you’re converting fewer cars in a more streamlined fleet, so you can do that within your existing budget.”

So, because EV choices on the market are currently limited, and practically non-existent where heavy vehicles are concerned, it’s imperative that transport operators also reduce their carbon footprint by optimising fleet efficiency.

Fleet Utilisation Self-Assessment

To decide which vehicles to remove and where vehicle use can be reduced, management should ask the following questions:

- Which cars and/or trucks can we remove from our fleet without significantly impacting operations?

- Do people need really to travel? Can digital means replace at least some face-to-face interactions?

- Can employees carpool or rideshare? What about public transport and micro-mobility vehicles like e-bikes and electric scooters?

- Can we phase out company cars as perks and incentivise staff in other ways?

- Can we use biofuels to help reduce emissions in our heavy fleet while we wait for technology and infrastructure to catch up?

Getting Everyone on the Same Page

Making changes and making them stick takes a concerted effort and the buy-in of all stakeholders. Telematics data can provide the fact-based evidence you need to validate fleet reduction and conversion decisions and inform future strategies.

For example, range anxiety, a worry about running out of power and having no available way to recharge, is a common objection but one that can be quickly debunked by data. Start by re-evaluating exactly what jobs need to be done and how far vehicles must travel to do them. In most cases, people have a poor awareness of actual distances travelled and greatly overestimate their range needs.

Accurate data on fleet utilisation is the key.

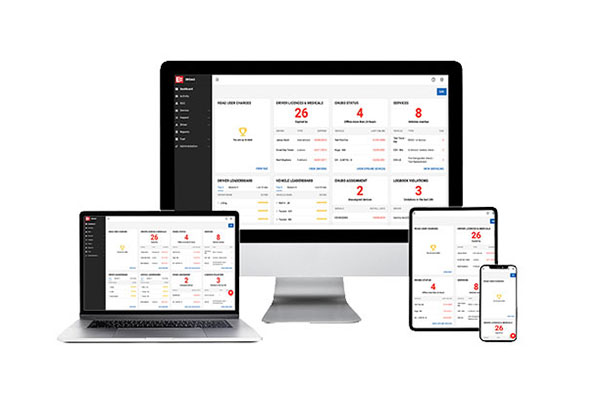

A telematics system takes away the guesswork by automatically logging all journey details and making them readily accessible for analysis. To draw meaningful conclusions, you should have at least six months’ worth of data. “That’s where the technology that organisations such as EROAD has perfected really comes into play,” says Briggs, “as how on earth can you manage what you’re not measuring?”

Telematics can tell you all sorts of useful things about driver behaviour, fuel usage, idling, and vehicle health to help you streamline operations, so they’re a worthwhile ongoing investment far beyond the initial scope of reducing and electrifying your fleet.

Because staff are the ones who will be driving these vehicles, they must be included in the journey from the outset. Educate your team on why and how you’re upgrading the fleet and have them test-drive similar models to familiarise themselves with how they work. Quite often, you’ll see the apprehension melt away.

Fleet managers will also need to retool their processes, since they will now be overseeing vehicles that require daily charging but far less repair and maintenance. Consider whether the car will be charged at work or whether it’s possible to install a charger at home, which will depend on owner or renter status as well as garage accessibility.

Your facilities manager also has a role to play in getting the business EV-ready. Is the existing power supply sufficient for the number of chargers you require? If not, who’s responsible for transformer upgrades and who pays for them, the landlord or the tenant? Installing smart chargers will allow for seamless billing and payment and could help negate the need for a site power upgrade.

What Will the Future Look Like?

While we don’t yet know what emerging technologies the market will adopt for heavy fleets – hydrogen, electric, or biofuel – with the Clean Car Discount, interest in buying light EVs has skyrocketed. Right now, you can get up to $8625 back from the government if you purchase an all-electric vehicle, and in about four years, EV price points will be comparable to those of ICE vehicles.

When you factor in total cost of ownership (sticker price plus the cost to run the vehicle less its residual value), electric vehicles can come out ahead, so cost should not be a barrier to making changes. You’ll also enjoy the benefit of new technology as it comes to market, for example cleaner air and a quieter ride, with no emissions. The planet is counting on all of us to do our part and do it sooner rather than later.

Are you looking to transition to EVs? Talk to EROAD to discover how telematics can guide smart operational decisions today and further down the track.