Transforming Trans-Tasman Operations

Transforming Trans-Tasman Operations

Thanks to EROAD, Hiway’s business units in New Zealand and Australia are more in sync than they’ve ever been. They’re more efficient, more profitable, and more compliant as well.

Founded in New Zealand in 1986, the Hiway Group is a civil contractor that operates throughout Australasia and the South Pacific, delivering ground improvement and recycling solutions for government, commercial organisations, and land developers. What began as a small family-owned and operated business has since grown into a trans-Tasman operation dealing in sustainable road and infrastructure repair and contaminated site remediation.

Since 2011, the Hiway Group has expanded exponentially in Australia, starting with Queensland before going nationwide. While momentous, this rapid expansion hasn’t been without its growing pains. The business saw EROAD as an opportunity to streamline their operations and get two different countries on the same page.

Automated Utilisation Reporting

Of the 200-plus plant items the New Zealand business uses day to day, half are heavy vehicles and utes operating on highways and construction sites, while the rest are a mix of civil construction equipment like graders, rollers, and stabilisers.

“We’ve got lots of plant all over the place, so it’s getting a handle on who’s using what and when so we can optimise our resource pool instead of buying new gear all the time, only for it to sit in a business unit and be poorly utilised,” says Adam Griffiths, business manager at Hiway New Zealand.

Automating Hiway’s utilisation reporting, or internal plant charges for each piece of equipment, was “one of the big wins we’ve had,” says Tom Gower, senior financial accountant. When he came on board two years ago, it was top of his most-wanted list – “something I wanted but didn’t think we actually would get.”

Previously, this was a manual exercise requiring significant administration time – 10 or more hours per week. “Chris, our transport manager, would sit down with his list of what he’d transported where,” explains Adam. “We’d match that up against pre-starts and also against timesheets.” Doing plant returns each week took Chris six to eight hours, which then had to be processed by admin and validated by the project managers. “You’re talking quite a significant input in terms of labour.”

Now, not only does Chris no longer have to perform this burdensome task, but “we’ve got accuracy in utilisation reporting, which is definitely a tangible benefit,” says Tom. “It’s accurate cost tracking, essentially.”

To achieve this, Tom spent four months working with EROAD to develop a custom report for Hiways. “It was one of those things that Hiway really pushed for, and I think that work could flow onto other customers in the civil space.”

The custom report uses geofencing to show where their plant was, how long it was operational for, and automates the whole weekly reporting process. Geofences are linked to job numbers, and equivalent hours are matched with the hourly or day rate for that piece of equipment then charged to that project.

“We might have anywhere from 10 to 70 jobs a month throughout the country,” says Adam, “and every job would have a minimum of three to four bits of equipment, maybe up to 10 with materials transport on top of that. So that scale for us is massive.”

While utilisation optimisation was their biggest driver when trialling EROAD, they quickly realised there were other benefits to be had. “Going from nothing to even the basic EROAD package was an amazing change,” says Adam. “We now had all this live information.”

Bigger Fuel Tax Credit Rebates

Based on the success of the three-month pilot trial in New Zealand, they quickly rolled EROAD out to Australia, which Tom has been heavily involved in, as his role has expanded to include systems deployment and improvement. EROAD has been useful in automating the regulatory requirements unique to each country.

“Legislation and accounting requirements alone are a massive piece of work,” says Adam. “You’ve got different project specifications and different ways of doing things. Here in New Zealand, we’ve got road user charges. In different states in Australia, you’ve got fuel tax and so on.”

“From a fuel tax credit reporting perspective, EROAD is completely changing the game for us,” agrees Tom. Previously, fuel tax credit reporting was done manually in Excel spreadsheets. “The benefit of EROAD is that we’re now getting accurate off-road usage and we’re currently able to go back four years and adjust our fuel tax claim.”

Because reporting in EROAD is so accurate, six months of data is sufficient to establish a pattern of use, enabling businesses to retroactively claim the maximum rebate they’re entitled to. With EROAD’s custom geofencing capabilities, Tom is projecting material gains.

“For a company like Hiway, where we’ve got trucks and plant out working and often required to be idling for long periods of time as part of their work, we’re getting a massive increase in fuel tax credits because you’ve got that consumption inside your geofence.”

Streamlined Pre-start Inspections

Adam and Tom also collaborated to standardise pre-start inspections for each class of plant across the group. “In Australia, we have a legal requirement to capture defects and have proof that we’ve repaired and closed those out,” explains Adam. “EROAD essentially does that for us.” Similarly, in New Zealand, if called upon to furnish proof of inspections, a business must be able to do so.

Uniformity across the businesses also lends itself to better intelligence. “That’s where pre-start standardisation comes in,” says Tom, “because you need the group all doing the same pre-starts for the same piece of equipment. Every data point needs to be consistent if you’re looking for valuable analysis.”

The EROAD Inspect module automates daily pre- and post-trip inspections and captures any issues or maintenance required on a defects board that flows through to service scheduling and fleet maintenance. “We’ve never had this kind of visibility before,” says Tom.

“The defects management system in the service module is by far the best I’ve seen on the market,” says Adam. “It has really streamlined the process with excellent visibility for all involved including the operators.

In the past, we relied on drivers to perform paper pre-starts, which were often not submitted in a timely manner, sometimes resulting in a duplication of efforts due to a breakdown in communication. “They’d send someone out to go and fix something and turn up to find that it was already repaired.” Never again!

The Future Looks Bright

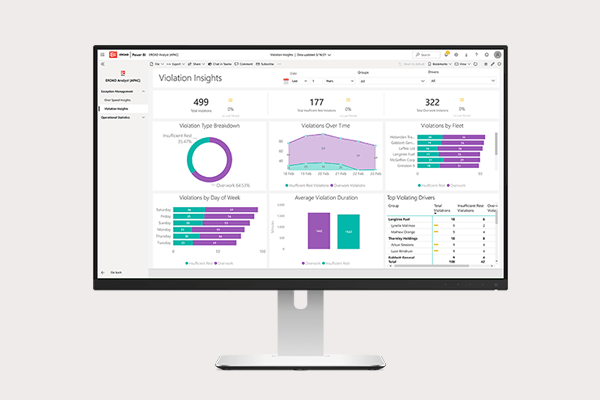

The thing Tom is most excited about is EROAD’s Snowflake data connector with Power BI, which enables you to easily extract all your historical data in a useable format.

“The insights we’ll be able to get from the data we’re holding in EROAD, that’s where we’re going to see the biggest benefit in terms of trend analysis. We can do all sorts of idling reporting and go deeper into utilisation reporting. We could build onto that custom report very quickly and customise it however we want. I mean, we get that weekly. We could get it daily if we start using Power BI. Essentially, predictive maintenance is where it could end up.”

By pulling EROAD data into Power BI, they’ll be able to identify trends at a granular level – “by plant class in terms of breakdowns and things like that. You’re essentially getting intelligence reporting out of EROAD, and that’s where we really want to get to”.

How much value? “It’s not just the cost of the repair,” says Tom. “It’s the opportunity cost to the customer, to us, lost earnings the following day”.

All in all, Adam, who has a long history of working with Hiway and EROAD, appreciates the team’s attentiveness and ongoing support. “Certainly, in the earlier days, they were on the journey with us. That’s brought us up to speed exponentially. It’s almost after-sales service, you could say.”